The technology of installing a soft roof does not require the use of special tools, therefore it is available and easy to perform. Shinglas shingles are installed on a single wooden panel, made of processed plywood or wood board. The very base rests on the rafters, on “pillow” of three elements: insulation, waterproofing and anti-condensation film.

For a tight fit and “gripping” of the adhesive layer, flexible shingles are installed when the thermometer is above five degrees Celsius, or in winter using a building hair dryer. When “cold” the base of the roofing material must contain modified bitumen.

Preparatory stage – preparing the base

An important condition – when wet, the base material should not exceed its “dry” more than twenty percent weight.

Air cushion – providing ventilation

The air passage gap should be at least fifty centimeters, the exhaust hole should be positioned as high as possible and the air inlet as low as possible, so that the required circulation will be achieved.

A well-organized air cushion when installing shingles will keep the room warm in winter and prevent overheating in summer, and will also help reduce humidity.

Underlay flooring

The overlap of the cover is ten centimeters. The substrate is fixed on the base with nails, the seams are glued.

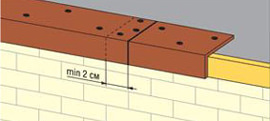

Fastening metal cornice strips

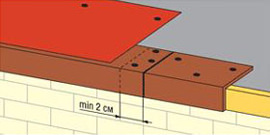

On all eaves, metal droppers are used to drain moisture, which are fastened with nails on top of the gasket layer with an overlap of two centimeters, in a zigzag manner, a step of one hundred millimeters.

Installation of metal gable strips

Installation of valley carpet

In the valleys on the lining are laid “carpet”, in the color of the tiles. The edges of the cover are fixed with roofing nails in ten centimeters increments.

Installation of cornice tiles

Fasteners for ordinary tiles

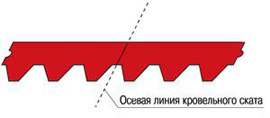

Laying should be done from the center of the eaves in the direction of the roof ends.

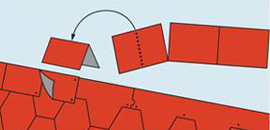

Installation of the ridge part

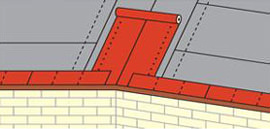

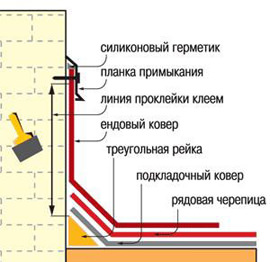

Fasteners for roof junctions

For chimneys, insulation and framing of tiles with a triangular strip 50 * 50 is required.

Using a sealing adhesive