The dry screed technology allows the floor to be leveled no worse and faster than the traditional solution using a grout. The result is the same smooth and ready-to-install any kind of flooring: planks, parquet flooring, laminate, floor tiles, carpet or linoleum.

After elementary calculations, you can make sure that a dry screed device will be cheaper than other options.

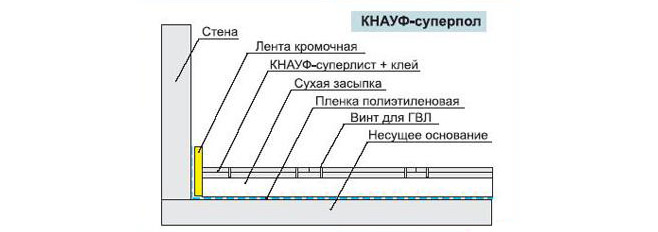

For the device of a dry floor screed, you will need the following materials:

- GVP sheets;

- expanded clay sand;

- polyethylene film;

- damper tape;

- glue;

- screws with double thread;

- rubber hammers;

- screw gun;

- laser level.

1. On the cleaned floor surface, a layer of waterproofing is laid out – a polyethylene film. Perimeter margin from 15 centimeters.

2. A damper tape (polyurethane or polyethylene) is laid around the perimeter of the room. According to the dry screed technology, the tape will prevent the formation of cracks during the period of temperature fluctuations.

3. Expanded clay sand is lightweight and serves as the main element in the device of dry floor screed. Sand is poured onto the prepared floor, starting from the highest point, and then moving to the lower level. For calculation, one bag occupies a square meter of floor with a thickness of five centimeters.

Expanded clay can vary in thickness from four to twelve centimeters. The device of a dry screed using expanded clay allows you to lay internal wired communications, in which case the backfill should be two centimeters above the corrugation in the final structure.

4. With the help of beacons, the layer of expanded clay is carefully leveled. Accuracy is checked using a level, the most accurate indicators will be given by a laser. The dry screed technology provides for the subsequent compaction of the expanded clay layer using rubber hammers, for greater strength.

5. Next, non-flammable, water-resistant SHP sheets (2 layers) are installed. For fixing, glue and double-threaded screws are used. At this step, all the main stages of the dry screed device end.

After all stages of the dry floor screed device, the structure should be allowed to shrink. The room must be warm and dry, the time “recreation” about two to three days. Due to shrinkage, the floor level will be as flat as possible, and the base will be strong.