Finishing Siding is a finish that refers to outdoor work and is intended for any residential buildings and outbuildings. Such cladding is also applicable for old houses, because the light weight of the structure is not capable of damaging the foundation..

The popularity of siding has been growing over the years due to:

- relatively low cost;

- long service life;

- high technical qualities;

- simple care;

- good protective properties;

- a large selection of colors and textures.

The big advantage is that you can give any building a modern look with your own hands, saving money on the service of specialists.

Which siding to choose?

Various types of siding can be used depending on the architectural features of the building and its operating conditions. Materials differ in terms of strength, load on the frame, care features.

- Vinyl siding made of PVC panel and varies in parameters depending on the manufacturer. It imitates wood, brick or natural stone cladding well. Perfectly matches any exterior. Among the advantages are resistance to deformation, lightness of the material, resistance to weathering. The disadvantage is that during installation, it is necessary to take into account the linear expansion so that the material does not undergo deformation during temperature drops..

- Wood siding is produced using antifungal impregnation with an antiseptic and must undergo high-quality drying at the factory. This will protect the material from mold and parasite growth. It is often used for finishing country and country houses. The advantage of this type of siding is good thermal insulation. The disadvantages include fire hazard, the need for painting, a short service life.

For finishing buildings can be used aluminum, galvanized and steel siding. An aluminum look is considered more decorative, which imitates the structure of a tree and lends itself well to painting. This material is not afraid of temperature extremes and does not rot. The disadvantages include the ability to deform and the likelihood of corrosion.

- Cement siding produced from high-quality cement with cellulose impurities. This type of finish effectively imitates a noble finishing stone. This material does not lend itself to the influence of atmospheric phenomena, does not rot or burn. But siding is heavy, which requires the organization of a reinforced frame and complicates its installation..

- Basement siding is a cement or PVC panel that accurately repeats the structure of a stone or brick. This material is produced with a thickness of more than 3 mm, since it is installed close to the ground and can be exposed to moisture and various damage.

Materials and tools

To complete the installation of siding, you will need tool:

- Scissors cutting metal, grinder, saw.

- Hammer, square

- Screwdriver set, electric screwdriver.

- Construction or laser tape measure.

- Folding ladder.

Today, siding is offered along with accessories for finishing houses of various configurations. When buying, the buyer just needs to specify the dimensions of the walls, the presence of windows, the type of roof and the consultant will calculate the required amount of material and cladding.

The work uses the following accessories:

- The outer corner covers the ends of the material.

- Internal corners connect the material to each other and to the wall surface.

- The cornice is sheathed with a wind dock and soffits.

- The starting bar is installed around the perimeter of the house, except for doors and gables.

- J-profile connects extensions, roofs of different levels and hide height differences;

- Window slats and tides frame the windows.

- Ebb and drain bar are installed around the perimeter of the base.

- An H-profile is used to connect the siding panels to each other, if it is necessary to add length.

- Siding.

- Use galvanized self-tapping screws to install the material, it is better to use self-tapping screws 25-35 mm long, which provides the necessary clearance of 1 mm.

How to sheathe a house with siding with your own hands: step by step instructions

Preparatory work

In the process of preparatory work, they produce dismantling of protruding wall elements, including doors, grilles, platbands. Around door and window openings, gaps must be repaired. The surface of the walls must be cleaned by removing dust, dirt, mold, chipped old finishes.

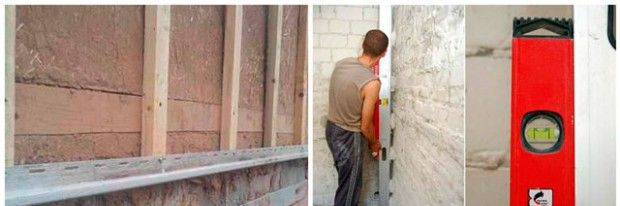

Installation of lathing

The panels must be fixed to the lathing. For vinyl profile are used wooden slats, which must first be treated with antiseptic agents and dried. For metal siding, it is better to install a frame from galvanized profile.

With a laser tape or level on the walls, straight lines are marked until a closed contour is formed. The next contour is drawn below, at the level of the basement, measuring the distance in the corners of the walls and finding the minimum indicator to the basement. This place will be installed starting bar. This process is very important, since it depends on whether the panels of the entire cladding do not warp..

At the corners of the wall, vertical guides, they are installed using U-shaped elements. These elements should fit snugly against the wall, this can be achieved with wood or foam pads. The guides should be positioned in increments of 30-40 cm. Near window and door openings, the number of guides is added due to additional mechanical stress. Vertical rails do not need to be connected to each other, this contributes to good ventilation.

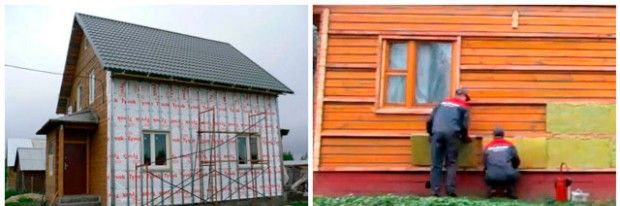

Warming and waterproofing

Wooden and aerated concrete buildings must necessarily have waterproofing. Insulation is installed at the request of the owner. It is better to give preference to a membrane with moisture and windproof properties. If the decision is made not to use insulation, then the membrane is attached to the surface of the walls, keeping space for ventilation. When using insulation, the waterproofing material is installed with the top layer, then a crate is installed to provide a ventilating space.

Installation of guide elements

Work begins with the organization of drainage to the basement. The top of the element is positioned along the intended line. Drainage Is a rigid element that can be easily installed in a flat position. Corner profiles are fixed firmly with self-tapping screws in the holes located at the top of the element. The following self-tapping screws need to be screwed into the middle of the hole.

Door and window openings are framed with J-profiles and window slats. For vertical installation, H-profiles are installed using a level. At the same time, a gap of 5 mm is provided at the ends to avoid deformation during expansion. In the area of the roof is installed finishing plank.

Panel mounting

The panels begin to be installed when all additional elements are mounted. The lowest row is fixed to the starting plate with a lock at the bottom of the element. The panel is attached with self-tapping screws in the upper part, they are screwed in every 40 cm.In the same way, all other siding panels are installed, rising with each row up to the roof. Siding must be movable, therefore, do not fasten it too rigidly. A finish panel is installed at the very top of the structure.

How to sheathe a house with siding with your own hands: video

Siding is the best way to quickly update the cladding of a building and protect the walls from the influence of atmospheric phenomena for many years. With proper installation and compliance with all requirements, the service life of this finish is about 30 years.

The panel installation process is not complicated and understandable even for non-professionals. It is enough to watch the installation video, study the instructions and recommendations and you can safely get down to work.